Digital Design Notes

Our digital designs share certain common characteristics.

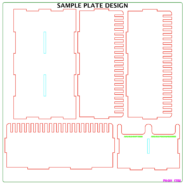

Plates

Our designs are laid out on plates that can then be packaged for commercial sale. Plates are numbered and plate size are optimized in almost all cases for Priority Mail flat-rate boxes for shipment. Our most common plate size is 300mm. We do have products that use smaller plate sizes. Our production process is designed to use 3′ x 2′ sheets of wood and so, generally, we yield 6 300mm plates per sheet of wood.

Colorization

As you are probably aware, colors in designs tell lasers to do certain things. We are a Trotec shop, so your colors may differ in purpose, but this guide will allow you to determine which of our colors should be change to different colors for your laser.

Generally speaking, there are three types of operations our designs employ: engraving, cutting, and etching.

Engraving is the rarer operation of the three for our designs. We rarely engrave anything other than our logo on designs due to the very time consuming nature of engraving.

The most common operation in our designs is cutting. We employ several colors for cutting. There is generally nothing special about each color other than the order they are cut in. Common colors used in our designs:

| Color | Color Code | Purpose |

|---|---|---|

| Black | engraving | |

| Red | cutting | |

| Dark Green | cutting | |

| Cyan | cutting | |

| Light Green | etching | |

| Purple | etching |

1) We do inner cuts first so that the material is always stable for these inner cuts. In this example cyan is used for inner-most cuts on pieces.

2) Red is then used to cut the pieces themselves. We cut using Trotec lasers and so we apply the links feature to our red cuts. This results in pieces that stay in the plate when handled because the laser turns the power down very quickly and then powers back up resulting in tiny tabs that hold the pieces in the plate. The pieces easily punch out when preparing to build. Many lasers do not offer a links feature, so designers often create tabs to hold pieces in the plate. These tabs generally require a hobby knife to cut through.

3) Finally, we then use another color such as green or dark blue for the final outer cut which defines the plate. This provides a uniform product when commercially packaging and shipping. If you are just cutting a design for yourself, the plate boundry is not really important other than for instructional purposes.

Finally, etching is simply low-power cutting. We mostly etch writing onto pieces. The idea is to not cut through the material, but simply to mark it. In this example plate, we etched using light green and purple.

Laser speeds are very specific to laser wattage, manufacturer, tube age, lens quality and cleanliness. You should test cutting and etching a sample piece until you dial in the proper speed and power.

Tolerances

Wood tolerances vary by producer. Most of our designs are mastered with inner cuts that are 3.1mm – 3.2mm. This means that the wood used can be 3.1mm or 3.2mm thick with no effect. However, this means that 99% of our kits require glue.